Introduction to the Manufacturing Execution System (MES) system of Crane-MES

Crane MES system gives the factory a strong transparent and digital management

capability. For the footwear industry, sponge product manufacturing and other

industries, the functions involve a wide range of functions - from production

planning, production schedule, to quality management and equipment maintenance,

the system can flexibly adapt to different process needs, to ensure the seamless

connection and accurate execution of each production link. With the help of

advanced automation and intelligent modules, the MES system plays an irreplaceable

role in the manufacturing process and becomes the core driving force for the

intelligent upgrading and efficient operation of the factory.

Crane MES is equipped with: login, user management, production management,

production kanban and other management modules.

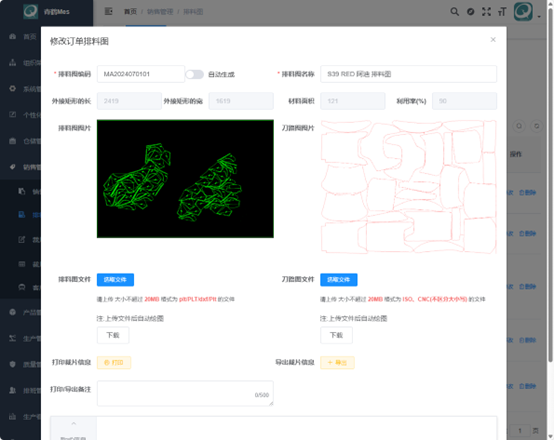

In Crane MES system, it includes the detailed tracking of key processes such

as parts, nesting diagrams, and toolpath diagrams, and also includes size,

raw materials, equipment management, and tool application into its efficient

control scope. In terms of order management, sales orders and production

order data are mapped to ensure a seamless flow of information.

Show Panle:

The MES system achieves a parallel of flexibility and rigor in data isolation and access control, providing enterprises with efficient and secure production management support.

In the intelligent interaction function of the Crane MES system, seamlessly integrated with the scheduling software, the system is endowed with powerful flexibility. Whenever the scheduling is completed, the generated scheduling diagram and tool path diagram can be directly transmitted to the MES system without any additional operations. The MES system will automatically recognize and match the pieces in the scheduling diagram, associating them with existing production instances; if a new piece that has not yet been recorded in the system is encountered, an instance will be created in real-time during the transmission process, ensuring the integrity of production resources and data. This intelligent collaboration not only enhances the accuracy of scheduling but also makes the production process smoother.

The Crane-MES system also provides powerful data printing and export functions,

allowing managers and operators to access production data at any time during

actual operations and print it in a concise and intuitive manner, creating clear

paper records. This flexible functionality significantly enhances the visualization

and operability of data.

Crane-MES Integrated Warehouse Management System: The following is the

Show Panle.